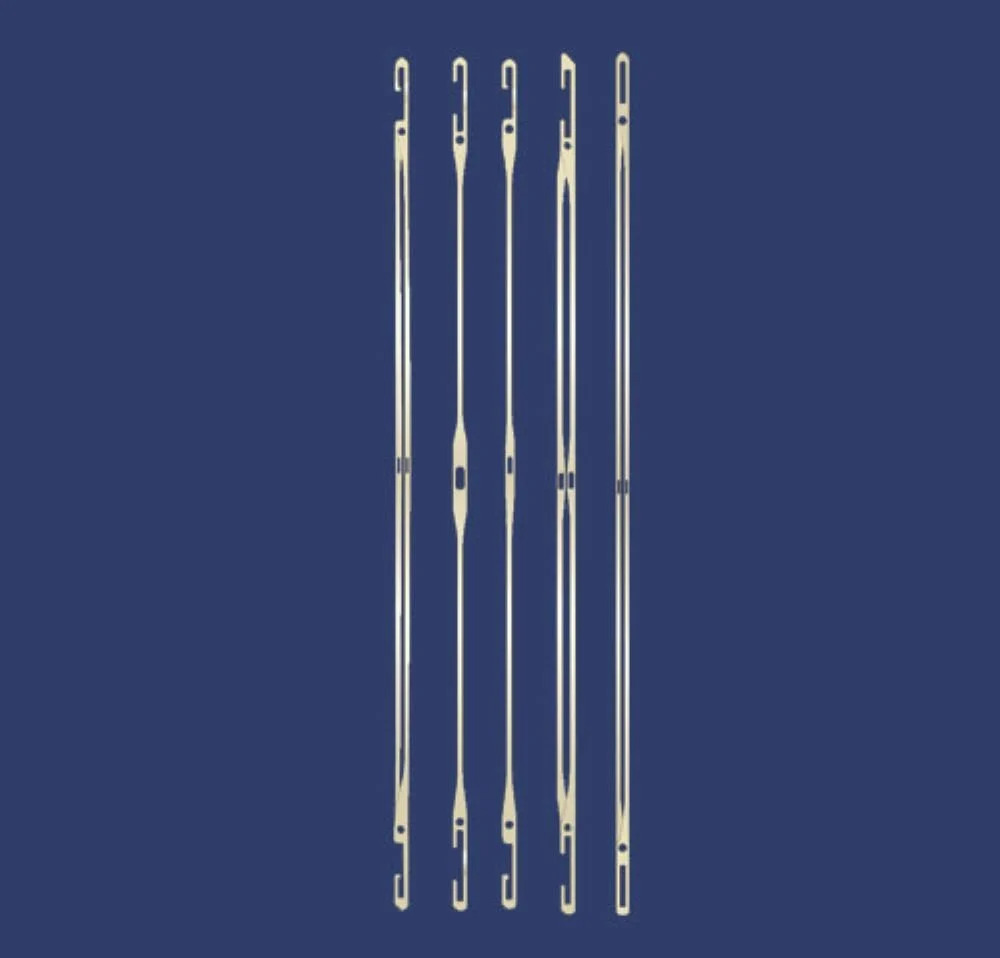

About Stainless Steel Wire Healds

Unlock a new era of weaving excellence with our Customizable Stainless Steel Wire Healds, tailored for diverse loom frame requirements. Ranging from 260 mm to 402 mm, each heald boasts an immaculate, polished surface finishmeritorious for top-notch performance and reliability. Manufactured in India by a leading distributor, exporter, and supplier, our stainless steel wire healds redefine durability and efficiency in textile machinery. Personalise your purchase for unparalleled weaving results, backed by a reassuring six-month warranty and engineered to meet premium quality standards.

Versatility and Advantages of Stainless Steel Wire Healds

Used for weaving loom frames, our Stainless Steel Wire Healds offer competitive advantages such as durability, rust resistance, and consistent performance. Their engineered precision and meritorious strength are invaluable in textile manufacturing, garment production, and specialized weaving applications. With top-notch material quality and customizable sizes, these healds elevate productivity and fabric quality across various weaving technologies.

Packaging, Export Markets, and Payment Terms

Order processing is seamless, with immaculate packaging details ensuring safety and integrity during transit. Our main export markets include Asia, Europe, and the Americas, catering to worldwide textile machinery needs. Payment terms are flexible, negotiated according to the customers asking price and transaction preferences, ensuring trust and simplicity in every export deal.

FAQs of Stainless Steel Wire Healds:

Q: How are Stainless Steel Wire Healds customized for different loom frames?

A: Our Stainless Steel Wire Healds are customizable in size, ranging from 260 mm to 402 mm, allowing precise adjustment to different loom frame specifications for optimal weaving efficiency.

Q: What makes the surface finish of these healds meritorious?

A: The polished surface finish enhances durability and reduces friction, contributing to the healds meritorious performance and the production of immaculate, high-quality textiles.

Q: When is the best time to replace wire healds in a weaving loom?

A: Wire healds should be replaced when signs of wear, deformation, or diminished weave quality are observed, or ideally within the six-month warranty window if any defects arise.

Q: Where can these wire healds be used aside from garment textile weaving?

A: Apart from textile weaving, these healds are suitable for specialty fabrics, industrial weaving processes, and technical textile manufacturing, wherever precise thread control is crucial.

Q: What is the process for ordering and exporting Stainless Steel Wire Healds?

A: Customers can initiate order processing by contacting our export team, receive detailed packaging information, and choose from flexible payment terms tailored to individual asking price agreements.

Q: How does using top-notch stainless steel wire healds benefit production?

A: Employing premium quality stainless steel wire healds ensures longer service life, enhanced productivity, reduced downtime, and consistently high weaving standards.